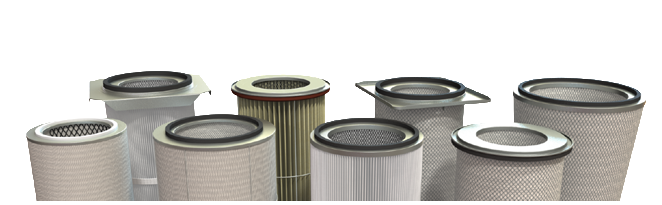

Baghouse Filter Solutions: Finding the Right Fit for Your Industrial Needs

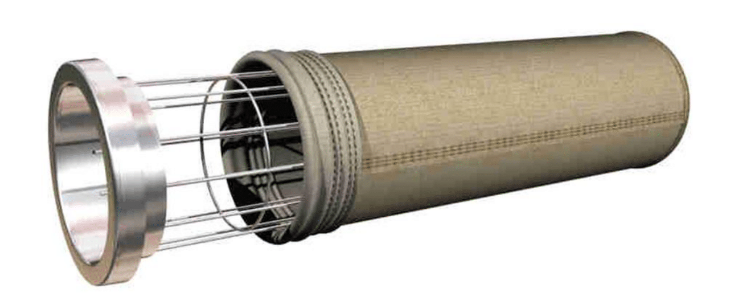

Baghouse filters are essential components in industrial air filtration systems, playing a crucial role in maintaining clean air quality and ensuring the efficiency of various manufacturing processes.