FAQ

Below is a list of frequently-asked questions. If you don’t find the answer to your question here, go to our “Ask A Question” page and fill out the form to have a representative contact you with an answer.

- On my pulse-jet collector every time a row of bags is cleaned I get a puff of smoke up the stack. Other than that the collector runs fine. What can I do to eliminate ‘puffing?’

- How often should I change my bags?

- How long should my filter bags last?

- I run a chemical plant and face enormous regulations not only for my emissions but also in the manufacturing, storage and transportation of our product(s). Are there any resources that address the chemical industry?

- How do I know if I need to have a permit for my baghouse or dust collector?

- I am right in the middle of an extended batch run with my baghouse and the dust collector just failed. It’s going to cost me a small fortune in penalties if I shut down to fix the baghouse. Normally I run a clean stack. Can my local regulatory agency cut

- I have started to see some smoke coming from my stack but it is barely noticeable. How much is too much?

- Is there a formula that I can use to determine the collection efficiency of my baghouse?

- Is there a formula that I can use to predict the collection efficiency of my baghouse?

- We have changed our process to run at a higher temperature. Now the inlet gases at the baghouse are too high for the type of bags we have in there . What can I do?

- I have spark carry-over from our processing ahead of the baghouse. How can I reduce the risk of fire in my baghouse?

- I have a high temperature (+300 degree F) baghouse that sometimes has heat excursions 25 degrees higher than the rating for the media I am using. These excursions only last a short while and then everything is back to normal…

- I just installed a new set of bags in my baghouse. Do I need to do anything special when I go to start it up for the first time?

- What is the proper fit of a filter bag onto a cage for a pulse-jet baghouse?

- What should I set my compressed air at for my pulse-jet baghouse?

On my pulse-jet collector every time a row of bags is cleaned I get a puff of smoke up the stack. Other than that the collector runs fine. What can I do to eliminate ‘puffing?’

If your baghouse is operating fine except during the cleaning cycle then you might be cleaning too frequently, have too light a dust loading, or the material collected is not conducive to building a dust cake in which case you should consider using a Precoat material or modifying the operation of the baghouse. If there is little or no dust cake on the bags the pulse action is doing nothing more than “working” the dust particles through the cross section of the filter media. Check your differential pressure at the time of cleaning. If you have “on demand” pulsing set the values to a higher delta P. If you have timed cycle cleaning lengthen the time between cycles.

How often should I change my bags?

Filter bags are a consumable item. They do wear out, blind off, burn up and get attacked by chemicals. Just like the oil and air filter in your car they need to be replaced to keep your collector running at optimum performance.

How long should my filter bags last?

Many factors affect bag life. Often collectors that were built with production rates in mind are now operating at twice their design load. Moisture and chemical upsets can take a set of bags out at startup. Typical design criteria on new installations should allow for a 2-year bag life. However, for difficult applications you can expect no more than a 3-month life if there are not other alternatives.

I run a chemical plant and face enormous regulations not only for my emissions but also in the manufacturing, storage and transportation of our product(s). Are there any resources that address the chemical industry?

There are several sources. The one comprehensive source we have found is OECD.org.

How do I know if I need to have a permit for my baghouse or dust collector?

More than likely you are required to have a permit, either state or federal for a baghouse or dust collector. Your first point of contact should be your local permitting authority for air pollution sources. Permits for businesses are usually administered at the state or local community level. Contact your State Small Business Assistance Program or your State Environmental Agency for assistance with this matter.

I am right in the middle of an extended batch run with my baghouse and the dust collector just failed. It’s going to cost me a small fortune in penalties if I shut down to fix the baghouse. Normally I run a clean stack. Can my local regulatory agency cut me some slack just so I can get this batch finished?

Don’t throw in the towel. You MAY have an out. Most districts have an equipment breakdown rule but they vary. California, one of the most advanced states regarding air pollution regulations, describes how the districts in their state approach this: “The conditions that a malfunction must meet in order to qualify for district breakdown provisions vary from district to district. Typically, the following are conditions for an acceptable breakdown:

- The breakdown must result from a failure that was unforeseeable;

- It must not be the result of neglect or disregard of any air pollution control law or rule or regulation;

- It must not be intentional, or the result of negligence;

- It must not be the result of improper maintenance;

- It must not constitute a nuisance; and

- It must not be an abnormally recurrent breakdown of the same equipment.”

There are reporting and time restrictions and you WILL get a visit from an inspector who may shut you down on the spot, but it is usually worth a shot. At least get a copy of your districts Breakdown Provision/Rule and go over it before you need to make a call.

I have started to see some smoke coming from my stack but it is barely noticeable. How much is too much?

The opacity of a plume is typically measured using a scale called a Ringlemann Chart as published in the United States Review of Mine Information Circular No. 1C8333, (May 1967), as specified in Health and Safety Code section 41701(b). A reading of 2 or less is usually acceptable. The reading normally cannot be done with the naked eye and requires a sampling by a qualified technician.

Is there a formula that I can use to determine the collection efficiency of my baghouse?

To determine collector efficiency divide the emissions (grainsSCFM) or mgCubic Meters by the incoming Grain Loading (grainsSCFM) . This will be the collector efficiency in percentage.

Is there a formula that I can use to predict the collection efficiency of my baghouse?

There is no single universal formula for any collector to predict collection efficiency. Many factors come into play especially the unique characteristics of the dust being collected.

We have changed our process to run at a higher temperature. Now the inlet gases at the baghouse are too high for the type of bags we have in there . What can I do?

You basically have two choices: Condition the gases to a lower the temperature, or change the filter bags to a type that is rated for the new higher temperature. Gas conditioning takes on three principal methods: dilution, radiation and evaporative.

Dilution of the exhaust gas stream by air is the easiest and cheapest method, especially at very high temperatures. However, air dilution requires the use of a larger baghouse to handle the increased volume of air. Other problems can arise due to the difficulty of controlling the intake of ambient moisture and other contaminants from the dilution air intake.

Radiation coolingcan also be used to lower the process exhaust gas temperature. Radiation cooling involves the use of long non-insulated ducts that allow the gas stream to cool as heat radiates from the duct walls. Ducts can be designed in “U” shapes to allow more duct surface area to be exposed for radiation cooling. Radiation cooling would not normally be very effective to cool gas temperatures below 572oF or 300oC. This would require substantial surface area, lengthy duct runs, and increased fan horsepower. Precise temperature control is difficult to maintain and there is a possibility of the ducts becoming plugged due to particle sedimentation.

Evaporative cooling is also used to reduce exhaust gas stream temperature. Evaporative cooling is accomplished by injecting fine water droplets into the gas stream. The water droplets absorb heat from the gas stream as they evaporate. Spray nozzles are located in a quench chamber or somewhere in the duct preceding the baghouse. Evaporative cooling gives a great amount of controlled cooling at a relatively low installation cost. Temperature control can be flexible and accurate. However, this cooling method may increase the exhaust volume to the baghouse. The biggest problem with evaporative cooling is keeping the gas temperature above the dew point of the gas (5O2, NO2, HCl, etc.). Otherwise, gases may condense on the bags causing rapid bag deterioration. In addition, all moisture injected into the gas must be evaporated to prevent corrosion of metal parts and blinding or plugging of the bags.

I have spark carry-over from our processing ahead of the baghouse. How can I reduce the risk of fire in my baghouse?

Spark carry-over is a major concern. At a minimum pin holes will develop in the media which will transfer dust to the exhaust stack. More serious cases result in fires. There is sophisticated equipment that detects and attempts to extinguish sparks within the ductwork prior to the baghouse. A crude but inexpensive method of spark reduction is the hanging of rows of chain in the ducting so that the sparks will strike the chain net and break up. It is often a matter that the baghouse is too close to the spark source, thereby not allowing enough time for the spark to die out prior to entering the baghouse.

I have a high temperature (+300 degree F) baghouse that sometimes has heat excursions 25 degrees higher than the rating for the media I am using. These excursions only last a short while and then everything is back to normal. Am I really affecting the life of the filters?

It is a misconception that short excursions above the rated temperature of a media do little harm. It is a fact that tensile strength effects are cumulative so eight excursions of one hour each in a given period would be the same as running for eight hours straight at the same reading. Often temperature related failures occur days after the event from a weakened bag flexing over that period. Know your process and if you think you will be spending any time exceeding the rated operating temperature of the media select a media with a higher temperature rating or anticipate a shorter bag life and the associated cost factors that go with it. High temperature baghouses should have continuous monitoring AND recording of temperature (strip chart, circular chart).

I just installed a new set of bags in my baghouse. Do I need to do anything special when I go to start it up for the first time?

Baghouse start-up after re-bagging is extremely critical. Improper start-ups are a leading source of immediate or premature bag failure. A well-executed start-up will insure a long useful bag life and optimum baghouse performance. Start-up procedures vary with both the temperature of the gas stream and the type of particulate being collected. Unless the baghouse is being used as the actual product recovery station for the powder, it is recommended that bags be conditioned with a pre coat powder. This powder is introduced near the baghouse inlet and coats the filter bags with a permeable cake that acts as a filter enhancement and protects the filter surface in case of abnormal particulates at start-up. Additionally you may elect or be required to leak test the baghouse. Check out our Maintenance Powders section for more information.

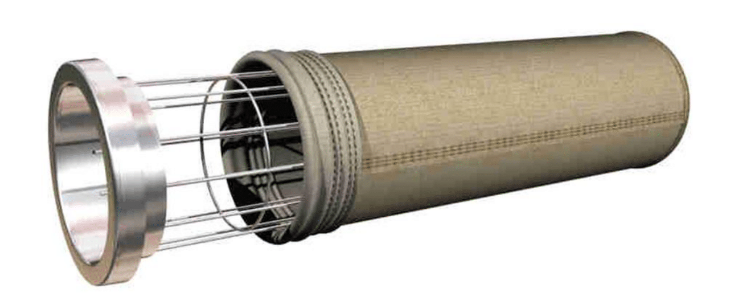

What is the proper fit of a filter bag onto a cage for a pulse-jet baghouse?

The “nip” or amount of the bag that can be pinched up from the cage, at a ring location, typically should be about ¼”-3/8″ for felts and 3/16″ for woven fiberglass. Excessive pinch will cause premature bag wear and allow for migration of dust through the cross-section of the media. Too tight a pinch will reduce the ability of the dust cake to release from the bag exterior.

What should I set my compressed air at for my pulse-jet baghouse?

The manufacturers of the baghouse usually have designed the unit to operate with a specified pulse pressure. In the absence of manufacturers recommendations some general rules can be applied. For a typical baghouse with 10′-12′ long bags the pulse pressure should be between 80-100 psig. Bags of 6′-8′ would be lower (60-80 psig) and bags of 14′ or more may require 120 psig or more to clean adequately. As a rule of thumb, the lower you set the pressure the more energy savings you will see as long as the inlet draw of the baghouse is operating satisfactorily.