Glossary

| Absorption | Process where one material consumes another as a homogeneous mixture in solution form |

| ACFM | Acronym for Ambient Cubic Feet per Minute |

| Acid dewpoint | The temperature at which acidic liquid droplets condense from the vapor phase. |

| Acrylic | Synthetic polymer fiber that goes by trade names Orlon, Draylon, and is composed of at least 86% acrylonitrile. There are two groups; Modacrylics and Homopolymers. |

| Activated Carbon | Carbon with a highly porous structure to provide filtration of odors and extremely fine particulates. |

| Agglomeration | The action where small particles group together to form larger particles or nodes of a scale anywhere from pea to golf ball size usually due to moisture or surface tension. |

| Air-to-cloth Ratio | The ratio of the amount of air entering the baghouse to the amount of surface area available for filtration. Optimal air to cloth ratios vary for different industry segments and types of dust collectors. Example: If the fan on a baghouse is capable of 100,000 CFM and the baghouse has 1000 bags of 6″ diameter x 12′ long (for a total filtration area of 18,850 sq. ft.), the A/C ratio would be 100,000/18,850 or 5.3:1 |

| Air, Standard | A specific value of dry air at 65oF and 29.92″ Hg pressure (Density 13.595 gm/cm3). Equivalent to 0.075-lbs/cu. ft. |

| Adsorption | A weak surface bonding of molecules in a fluid phase (gas) through physical or weak chemical attraction. A good adsorbents is characterized by a high surface-to-volume ratio (e.g. activated carbon). |

| BACT | Acronym for Best Available Control Technology. A standard for permitting of baghouse and dust collectors that takes into account the impact of energy and equipment costs in balance with environmental needs in new or retrofit applications |

| Baffle | A plate, grating, or refractory wall used especially to block, hinder, or divert a flow. The baghouse inlet typically has the highest velocity. Particulate will sandblast the lower portion of the bags in the baghouse in the absence of a baffle. |

| Batch cleaning | As a textile term refers to the process used in heat-cleaning glass filter cloth prior to converting into a filter by exposing it to 500-600oF temperatures for prolonged periods to burn off the starches and other lubricants used to assist in the weaving process. |

| Bleed | When particulates are so fine that they pass through the cross- section of the filter media and exit the baghouse. If the dust cake is poorly managed or there is little dust loading bleeding is likely to occur. |

| Bleed-through | Particulate that migrate through the filter media are discharged up the stack. |

| Blinding | Particulate that accumulates within and/or on the surface of the media such that the flow passages for the gas are blocked restricting the flow and resulting in high pressure drop. |

| CAA | Acronym for Clean Air Act |

| Can Velocity | Velocity of the baghouse process air as it flows upward through the rows of bags. Formula: Area of the Baghouse in square feet minus the area of the diameter of the filter bags divided by the ACFM of the process air. Excessive Can Velocity can cause premature bag wear due to abrasion and can cause more dust to be carried upward to the bags overloading the bags and the cleaning system. Conversely a Low Can Velocity can cause segregation of the incoming dust carrying only the finest of particles which may prevent the formation of a good Dust Cake. |

| Capture Velocity | The air velocity at any point in front of the hood or at the hood opening necessary to prevent particulate material and contaminant gases from escaping into the working area. |

| CEM | Acronym for Continuous Emissions Monitoring. The measurement and reporting of specific pollutant levels at a facility. |

| CFM | Acronym for Cubic Feet per Minute. A unit of measure for volumetric flow of a gas. |

| CFR | Acronym for Code of Federal Regulations. The Clean Air Act is located in 40 CFR For a layman’s look at the Clean Air Act click here. |

| Clean Air Act | Originally passed in 1955 and since amended in 1970, 1977 and 1990, the Clean Air Act sets controls at the federal and state levels for air pollutants a.k.a. “the 800-pound gorilla.” |

| Concentration | Amount of dust in the gas. Usually expressed in terms of grains/ cu ft, Ib/l000 Ib. of gas, ppm, mg/cu mt. or Ib/million Btu. |

| Criteria pollutant | An air pollutant for which a national ambient air quality standard has been promulgated. |

| Cyclone | A conical-shaped vessel for separating mixed sized particulates from the gas stream. The vessel has a tangential entry at the largest diameter allowing larger particles to drop out and be removed from the bottom of the cone while smaller particulate exits overhead with the majority of the gas stream. |

| Damper | An adjustable gate installed in a duct for the purpose of regulating airflow or introducing outside air to the ducting system. |

| Denier | The weight, in grams, of 9000 meters of a single fiber strand. |

| Dew point | The temperature where water molecules in a gas will begin to condense and form a liquid. |

| Diaphragm Valve | A compressed air operated valve used to deliver air in short bursts to pulse clean bags. |

| Differential Pressure | In a Dust Collection System, the Differential Pressure usually refers to the difference in pressure (typically measured in inches of water column W.G.) between the dirty side of the baghouse and the clean side of the baghouse. Essentially this yields the pressure drop or resistance to the air-flow through the filter bag. |

| Dispersion model | A computerized set of mathematical equations that use emissions and meteorological information to simulate the behavior and movement of air pollutants in the atmosphere. The results of a dispersion model are estimated outdoor concentrations of individual air pollutants at specified locations. |

| Dry scrubber | A chemical reaction chamber that neutralizes acids in a gas stream. There are two common system types: the spray dryer system that injects a slurry; and a dry sorbent injection system that uses a dry powder. |

| Dust Cake | Essential buildup of porous dust layer on the surface of a filter, which significantly increases the efficiency of the filter. Proper management of the dust cake also effects useful life of the filter. |

| Dust Loading | The amount of particulate (by weight) that is suspended in a gas stream at the baghouse inlet usually expressed in grains per cubic foot. See also Grain Loading. |

| EPA | Acronym for Environmental Protection Agency. The federal agency responsible for developing and enforcing environmental policy in the United States and its territories. |

| Epitropic Fiber | Fiber whose surface contains embedded particles to modify one or more properties of the fiber, typically electrical conductivity. |

| ESP | Acronym for Electrostatic Precipitator. A device that collects particulates by placing an electrical charge on the particulate and attracting them onto a collecting electrode. |

| Felled Seam | Vertical seam in a filter bag, typically a nonwoven, which requires an overlap of the material. See also French seam. |

| Felt | Fabric structures constructed by the interlocking action of the fibers them- selves, without spinning, weaving, or knitting. |

| Filter Cake | The accumulation of dust on a bag. Often assists in the filtration process. Also see Dust Cake. |

| Filter Media | The permeable barrier employed in the filtration process to separate the particles from the fluid stream. |

| Flue gas | The gases emitted into the atmosphere from a production or combustion process through the flue or “smoke stack.” |

| Fly ash | Gas-borne particulate resulting from the combustion of fuels, typically fossil fuels such as coal and lignite. The ash is composed of a variety of oxides and silicates depending on the fuel and efficiency of the combustion process. |

| Fly Ash | Finely divided particles of ash entrained in flue gases resulting from the combustion of fuel. The ash particles consist of incompletely burned fuel and a variety of mineral constituents. |

| French seam | Vertical seam in a filter bag, typically a woven, which requires a doubling over of the material. See also felled seam. |

| Fugitive dust | Emissions from a process or control that occurs at points other than stacks or vents. |

| Glazing | High pressure pressing of the filter medium at elevated temperatures; fuses surface fibers to the body of the filter medium. |

| Grain | Weight unit of measure where one pound equals 7000 grains. |

| Grain Loading | The amount of particulate (by weight) that is suspended in a gas stream at the baghouse inlet. See also Dust Loading. |

| Ground Wire | Braided metal strip, usually copper or stainless steel, placed on or in the seam and grounded to the collector to assist in dissipating static build-up caused by the gas flow. |

| HAP | Acronym for Hazardous Air Pollutant. A list of nearly 200 pollutants has been classified under this heading by the Clean Air Act Amendments of 1990. Standards were to have been adopted no later than November 15, 2000. Click here for the list of the Top 33 that they will be focusing their efforts on. |

| Hydrocarbon | A chemical compound containing only molecules of carbon and hydrogen. |

| Hydrolysis | A chemical reaction in which water reacts with another substance, either dust or the filter media, breaking the chemical links and creating two or more substances. The presence of water in a baghouse is a significant detriment to the filter media. See also Dew point. |

| Hydrophilic Fiber | Fiber that readily absorbs water. |

| Hydrophobic Fiber | Fiber that does not readily absorb water. |

| Inversion | The occurrence of a layer of cool air trapped beneath a warmer layer and the cooler layer not warming and dispersing upward. The emissions at ground level are trapped and remain concentrated creating high concentrations of pollutants. |

| LAER | Acronym for Lowest Achievable Emission Rate |

| Lime | Common name for calcium carbonate as it is found in the ground. When heated in a kiln, it yields “burnt” or “quick” lime (calcium oxide). When lime is hydrated or “slacked” it becomes calcium hydroxide. |

| MACT | Acronym for Maximum Achievable Control Technology |

| Magnehelic Gauge | Instrument to measure the differential pressure between the dirty (inlet) and clean (outlet) sides of a baghouse. As a general rule differential pressures greater than 7in. W.G. indicate serious performance problems with the unit and require investigation . |

| Major source | As defined by The Clean Air Act Amendment of 1990: “any stationary source or group of stationary sources located within a contiguous area and under common control that emits or has the potential to emit considering controls, in the aggregate, 10 tons per year or more of any hazardous air pollutant or 25 tons per year or more of any combination of hazardous air pollutants.” |

| Manometer | An instrument for measuring pressure; a U-tube partially filled with liquid, usually water, mercury or a light oil, so constructed that the amount of displacement of the liquid indicates the pressure being exerted on the instrument |

| Micron | A unit of measure equal to 1/1,000,000 of a meter |

| MIT Flex | A test whereby a filter media specimen is rapidly flexed in an arc under a specified load until fabric rupture occurs. Test conditions are usually: 270° arc, 180 cycles/minute, 4-pound load, 1/2-inch width specimen. |

| Mullen Burst Test | Standardized ASTM test method to measure the strength of a filter material under multidirectional pressure expressed in pounds per square inch. |

| NAAQS | Acronym for National Ambient Air Quality Standards |

| NESHAPS | Acronym for National Emissions Standards for Hazardous Air Pollutants. A federal requirement setting standards and limitations for monitoring and reporting of carcinogenic discharges into the atmosphere. |

| Non-Attainment | When pollution criteria being monitored exceeds the national or regional level set for that particular pollutant. |

| NSPS | Acronym for New Source Performance Standards |

| Opacity | A measurement of the density of emissions in the plume of a stack. |

| Osmosis | The diffusion of a solvent through a semi-permeable membrane into a more concentrated solution. |

| PEL | Acronym for Permissible Exposure Limit. The allowable exposure level in the workplace for a particular pollutant over an 8-hour shift. See also TWA. |

| Permeability | A measurement of the ability of air to flow through a filter at a given differential pressure. The value is expressed as (U.S.) cubic feet per minute at .5″ water gauge differential or (Metric) liter/min at 20mm water gauge differential. |

| pH | The measure in units from 0-14 of the acidity or alkalinity of a stream of gas or liquid. A pH of 7 is neutral. Values below 7 tend towards acidic; values above 7 tend toward alkaline. |

| Pitot tube | A sensing unit inserted into the gas stream to measure gas velocity based on a differential between the total pressure and the static pressure. |

| Plenum Chamber | An air compartment maintained under pressure, and connected to one or more ducts. A pressure-equalizing chamber. |

| PM10 | A USEPA standard that includes additional controls on particulates sized 10 micron and smaller |

| PM2.5 | A USEPA standard that includes additional controls on particulates sized 2.5 micron and smaller |

| Pre-coat | Material added to the air stream in the initial process startup to aid in establishing a filter cake on the bags. Pre-coat is good insurance for an operation that may introduce harmful by products if the initial start up does not go as planned. (e.g. incomplete combustion from a failed burner start up sending unspent hydrocarbons to the baghouse, latent moisture upstream of baghouse, etc. ) or to get immediate high filtration efficiencies with a pre-built dust cake. |

| Pressure Drop | Resistance to gas flow; may refer to apressure differential across the cloth, across the baghouse, or across the entire system. Units are usually inches of water. |

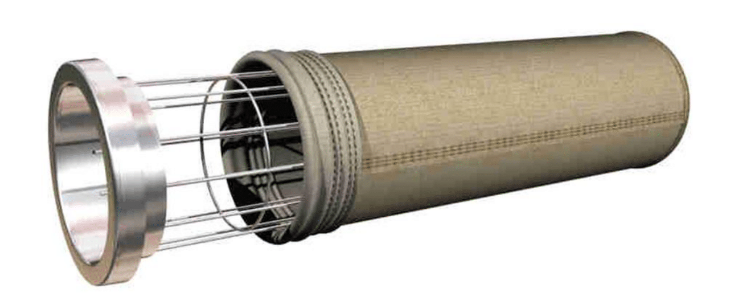

| Pulse-jet | Type of baghouse design where dust is collected on the exterior of a filter tube, supported by a cage, and cleaned with a rapid pulse of compressed air driven down the interior of the filter tube. |

| Reagent | |

| Reverse-air | Type of baghouse design where cleaning is accomplished by reversing the flow to a portion of filters and dislodging the dust. |

| Scrim | A very loosely woven fabric onto which felt is needled to add dimensional stability and strength. Use of scrims is declining as high performance textile equipment is allowing for the creation of 100% fiber media with the same or superior strength characteristics. |

| Self-supported | A nonwoven fabric that has been processed to interlock the fibers such that a scrim is not required. Self-supported filter materials have established themselves as the most popular choice for low temperature applications. However, high temperature applications of self supported fabrics, especially in long bag configurations, should be approached with caution and on a case by case basis. |

| Shaker | Type of baghouse design where the filter bag is agitated by mechanical means to dislodge the dust. |

| Singeing | Passing of the filter medium over an open flame, thereby removing the protruding surface fibers. Singeing the collection side of the filter allows for easier dust cake removal. |

| Sonic Cleaning | Sonic energy from air-powered horns produces shock waves, which enhance dust removal from fabrics. Sonic cleaning is typically used in reverse-air application involving a fiberglass bag. |

| Specific gravity | The ratio of a mass of a unit volume of a substance to the mass of the same volume of a standard substance at a standard temperature. For gases, dry air at the same temperature and pressure as the gas is often taken as the standard substance. |

| Spunbonded | A non-woven fabric formed by producing, laying and self-bonding a web of filament material in one continuous set of processing steps. Usually made of polyester, polyamides or olefins. |

| Staple Fiber | Short fiber cut to specific length in synthetics to either form yarns or non-woven felts. The size, distribution and type of fibers used in the filtration vary to suit process needs. Selecting the right combination is essential for maximum performance. |

| Venturi | An air affect passage that gradually contracts to a smaller opening and expands again at a different rate thus causing acceleration of flow and gradient pressure change. Venturi’s are typically used in pulse-jet cages to enhance the pulse clean cycle. However they also restrict normal flow as well and add to system delta P. |

| VOC | Acronym for Volatile Organic Compound |

| Warp | The yarn running lengthwise (machine direction) in a woven fabric. |