Baghouse filters are essential components in industrial air filtration systems, playing a crucial role in maintaining clean air quality and ensuring the efficiency of various manufacturing processes. Selecting the right baghouse filter solution for your specific industrial needs is paramount to achieving optimal filtration performance, longevity, and cost-effectiveness. This article will provide a comprehensive guide to understanding baghouse filters and the key factors to consider when choosing the right filter solution for your industrial applications.

Understanding Baghouse Filters

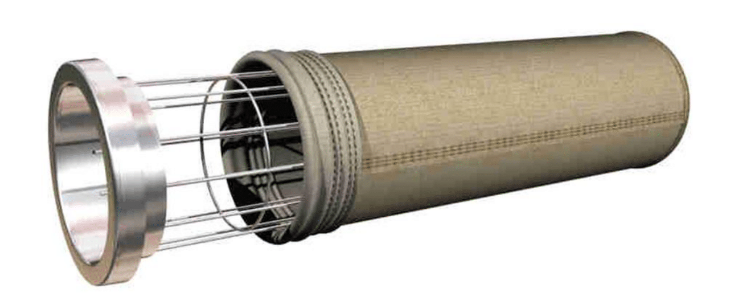

Baghouse filters, also known as fabric filters, are air pollution control devices used to remove particulates, dust, and other contaminants from industrial air streams. These filters consist of a series of fabric bags or tubes that capture particles as the air passes through them. Baghouse filters are widely used in industries such as cement, steel, pharmaceuticals, and food processing, where maintaining clean air quality is critical for both environmental and operational reasons.

Factors to Consider When Selecting Baghouse Filters

- Filter Media Selection:

- Different types of filter media offer varying levels of filtration efficiency and durability.

- Polyester filter media are known for their high efficiency and resistance to moisture and chemicals.

- Polypropylene filter media are suitable for applications with high moisture or chemical exposure.

- Acrylic filter media offer good resistance to abrasion and high temperatures.

- Fiberglass filter media are durable and can withstand high temperatures and corrosive environments.

- Baghouse Design Considerations:

- Airflow and Air-to-Cloth Ratio: Proper airflow is crucial for efficient filtration. The air-to-cloth ratio, which is the ratio of air volume to filter area, should be maintained within optimal limits to prevent overloading or underutilization of the filter media.

- Dust Loading Management: Proper management of dust loading is essential to prevent filter clogging and maintain airflow. Regular cleaning and maintenance practices, such as pulse-jet cleaning or reverse air cleaning, help extend the life of the filter media.

- Cleaning Mechanisms: Different baghouse designs use different cleaning mechanisms to remove accumulated dust from the filter media. Mechanical shaking, pulse-jet cleaning, and reverse air cleaning are common methods used to clean baghouse filters.

- Supplier Selection:

- Choosing a reputable supplier is crucial for ensuring the quality and reliability of baghouse filter solutions.

- Consider factors such as the supplier’s experience, reputation, and track record in providing customized solutions for industrial air filtration needs.

- Look for suppliers that offer comprehensive support services, including technical assistance, maintenance, and replacement parts.

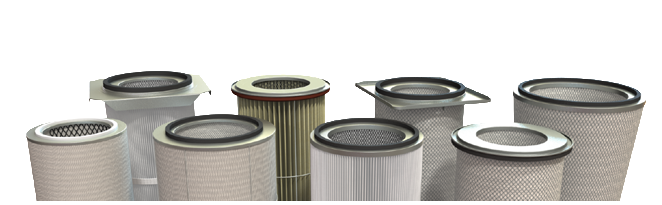

Standard Filter’s Baghouse Filter Solutions

Standard Filter is a leading provider of baghouse filter solutions, offering a wide range of filter media options, baghouse designs, and cleaning mechanisms to meet the diverse needs of industrial applications. With decades of experience and a commitment to innovation and quality, Standard Filter is a trusted partner for industries seeking reliable and efficient air filtration solutions.

Conclusion

Selecting the right baghouse filter solution for your industrial needs requires careful consideration of factors such as filter media, baghouse design, and supplier reliability. By understanding these key factors and consulting with a reputable supplier like Standard Filter, you can ensure optimal filtration performance, longevity, and cost-effectiveness for your industrial processes.