In today’s increasingly competitive business environment, companies are constantly seeking ways to optimize efficiency and maximize profitability. Every aspect of an operation, from raw materials to finished goods, needs to be scrutinized for potential improvements. While the focus often falls on large-scale investments and process changes, a crucial element that can significantly impact the bottom line is often overlooked: the quality of your dust collector filter bags.

Choosing the right filter bags for your specific needs is not simply a matter of filtration; it’s a strategic decision that can influence a wide range of operational aspects, ultimately leading to substantial financial gains. This case study will demonstrate how investing in high-quality filter bags can be a game-changer for your operation’s bottom line.

The Costly Impact of Inefficient Filter Bags:

Many companies continue to operate with outdated or inappropriate filter bags, unaware of the detrimental impact they have on their bottom line. These inefficient filters often lead to:

- Increased energy consumption: Clogged filter bags restrict airflow, forcing the dust collector fan to work harder. This higher energy demand translates to increased electricity costs, impacting profitability.

- Reduced production output: Limited airflow due to clogged filters hinders the efficiency of your dust collector. This leads to production delays, missed deadlines, and ultimately, lost revenue.

- Excessive maintenance costs: Inefficient filters require frequent cleaning and replacement, leading to increased downtime and labor costs. Moreover, low-quality filters can damage internal components of the dust collector, resulting in costly repairs.

- Environmental compliance concerns: Failure to maintain proper filtration efficiency can contribute to increased dust emissions. This can lead to fines and penalties from regulatory agencies, further impacting your bottom line.

Investing in Efficiency: The Standard Filter Solution:

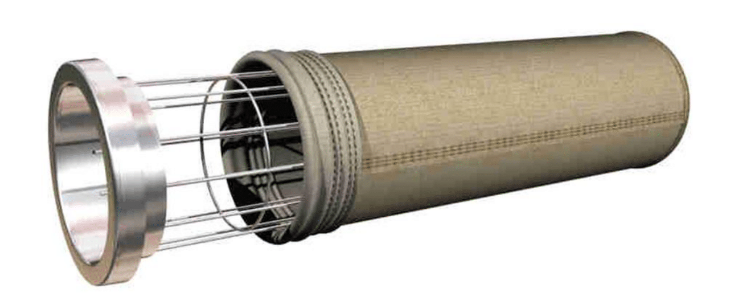

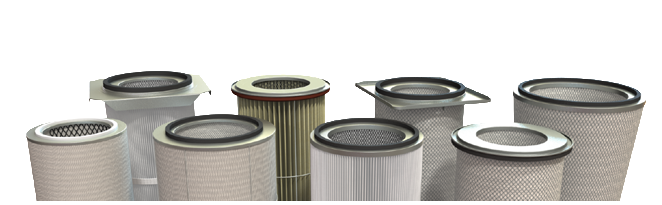

Standard Filter provides a comprehensive solution to these challenges by offering a diverse range of high-performance filter bags specifically designed to meet the diverse needs of various industries. We understand that there is no one-size-fits-all solution, and we work closely with each customer to identify the ideal filter bags for their unique application.

Here’s how choosing Standard Filter can benefit your operation:

- Enhanced filtration efficiency: Our meticulously designed filter bags capture even the finest dust particles, ensuring optimal air quality, preventing harmful emissions, and creating a cleaner work environment. This leads to improved product quality, reduced environmental impact, and potentially reduced compliance-related costs.

- Extended filter life: We utilize premium materials and advanced construction techniques to ensure our filter bags offer exceptional longevity. This minimizes downtime for replacements, reduces maintenance costs, and increases the overall efficiency of your dust collector system.

- Reduced energy consumption: High-efficiency Standard Filter bags boast a lower pressure drop, allowing your dust collector fan to operate at a reduced power, significantly lowering energy consumption and contributing to cost savings.

- Boosted production: By maximizing airflow and filtration efficiency, our filter bags ensure peak performance for your dust collector. This enables uninterrupted production and increased output, ultimately leading to higher profits.

- Reduced maintenance: With extended filter life and minimal pressure drop, our filter bags require less frequent maintenance and cleaning, minimizing downtime and associated labor costs.

Unlocking the Potential: A Concrete Example:

A leading cement manufacturer was struggling with significant challenges due to their inefficient dust collector system. Frequent bag failures, high energy consumption, and reduced production were impacting their bottom line. After switching to Standard Filter’s high-efficiency filter bags, they experienced remarkable improvements:

- 20% increase in filter life: This led to reduced downtime and maintenance costs, saving the company valuable resources.

- 15% reduction in energy consumption: Lower energy bills contributed to significant cost savings and improved the company’s environmental footprint.

- 10% increase in production output: Increased production capacity resulted in higher revenue and profitability for the manufacturer

- Improved air quality: A cleaner work environment enhanced worker safety and reduced the risk of respiratory issues, further contributing to employee well-being and productivity.

Conclusion:

In conclusion, choosing the right filter bags is an investment that can yield significant dividends for your operation. By optimizing dust collection efficiency with Standard Filter’s high-performance filter bags, you can expect a range of benefits, including reduced energy consumption, increased production output, extended filter life, lower maintenance costs, and improved air quality. These combined benefits translate to a positive impact on your bottom line, enhancing your competitiveness and driving long-term success.

Contact Standard Filter today to schedule a consultation and discover how our tailored solutions can optimize your dust collection system and boost your operation’s profitability.