Season after season almond huller facilities are making one mistake that is costing them thousands of dollars a year. Ironically, this one mistake is adding extra production hours, increased energy cost, lost productivity, extra wear and tear on equipment, and increased emissions. This mistake is actually motivated by an attempt to reduce cost. Let’s dive into what is discreetly eating at your profits.

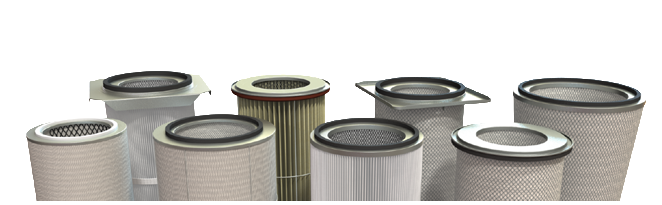

At the end of the season almond hullers will undergo a number of routine maintenance procedures that get the facility ready for the next harvest. One of the things they do is make repairs on the baghouse systems to get them in working order. That includes taking out old filters and replacing them with new ones; or sending them off to be cleaned by companies that specialize in filter bag laundering. Here is where the problem starts.

Hulling facilities have an option to buy new filters or wash the ones they currently have. For most plants the choice is clear. Washing filters instantly looks like the best option to save money. A facility will see the cost to wash filters (average $4.50/each) vs new filters (average $11.50/each) as significantly lower. Let’s assume a facility uses 1,000 12′ LMC Style filters. By sending them off to be cleaned the cost would be around $4,500 (not including shipping cost). A new set of filters will cost around $10,500! It is safe to assume most people would jump on $6,000 of savings and opt to have the filters washed. The real question is are you really saving $6,000 per season by cleaning your filters? The answer may surprise you. First, we need to understand what a baghouse is, and how it works.

What is a baghouse and how does it work?

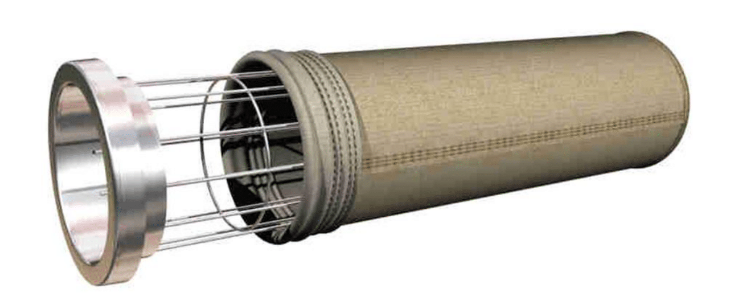

A baghouse is an air pollution control device that uses fabric filters to remove dust out of air released from a commercial process. Baghouse’s work by pulling dust latten air into the system, where dust particles accumulate on the “dirty side” of fabric filters. The clean air is allowed to pass through the media and back out into the environment. The fabric filters play the biggest role in the baghouse operations. This is why it is important to insure filters are allowing the intended amount of air to pass while removing as much dust as possible. Filters alone are not actually efficient at removing dust. They work by what is called, a buildup of the “filter cake”. This filter cake is an accumulation of dust on the surface of the media. The filter cake creates a barrier that captures finer incoming dust. Without this filter cake smaller dust particles would just pass right through the filter media. The filter cake also plays a role in protecting your filters. For instance, small particles have a potential to penetrate the outer fibers and enter deep into the media. This is called “depth-loading” Click here to read more on Depth-loading and once dust has entered into the media you will notice permanent pressure rise. Over time you will be forced to replace all the filters to reestablish proper airflow.

Does your facility buy new filters or wash them?

After the season is complete almond hullers focus their attention on getting the baghouse back in working order. One part of that is figuring out what to do with the filters. Do we replace them all or send them off to be washed? Calling a local filter cleaning company is a commonly held practice within the almond hulling industry. Some facilities follow the same practice they have always done. Year after year a set of filters are sent off to be washed and returned.

What is wrong with having my filters washed?

The almond huller industry is one of the few industries that may see some value in recycling a set of filters by sending them off to be washed. The problem is when the filters are being washed year after year. This year after year cleaning routine causes major problems with filters. Here is what happens to filters that are being cleaned year after year.

- Cleaning starts to weaken the filter media, causing holes.

- Cleaning will damage the media pores causing two things – the media allows too much air to pass, or not enough.

- Cleaning will cause the finish of the media to be washed off.

- Increased likelihood of Depth-loaded filters requiring more energy and resources to clean

- Running your baghouse into the ground-resulting in a poorly performing baghouse.

Now let’s get into specifics on how each issue is costing your plant money.