Read the Part 1 of this article

This week we will be delving into these points in detail. Lets get started!

1. Cleaning starts to weaken the filter media

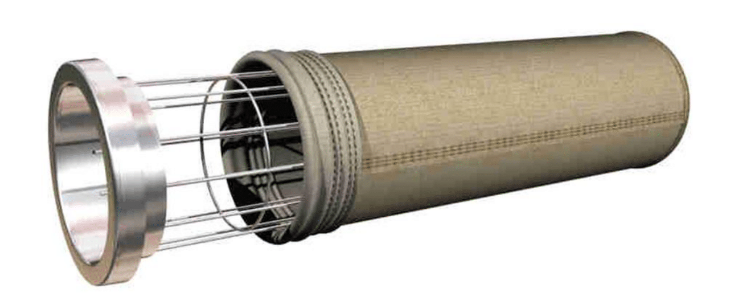

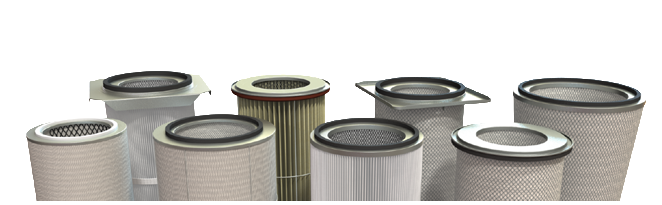

The most common media used by almond hulling facilities is a 16oz needle punched polyester felt. This media is made by hundreds of needles punching fibers into one another. The punching causes fibers to interlock with one another. This interlocking of polyester fibers is what holds the media together. The most common method of washing filters looks pretty similar to what we do to wash our own shirts and jeans. A large machine uses an agitator to move the filters around with water. A result of this method is the interlocked fibers start to separate. The more you wash, the weaker the weave becomes. Overtime thin spots will develop and cause holes. Think of cleaning your favorite jeans over and over again. At some point the denim weakens causing holes to develop in tension points like around the knees. Same theory applies to felt media. The problem is holes can develop at any time. This could mean right in the middle of the season. Every plant operator has experience the following. All of a sudden you notice a drop in differential pressure. So you stop production, turn off the baghouse, and open the baghouse to find where the leak is coming from. In a collector with 1,000 filters that can take time. In fact, once a leak or rupture has occurred it can take at least 4-8 hours, depending on how experienced your maintenance team is, before you get back on line. Unknowing to the plant is the decision to wash the filters has led to a weaken filter highly prone to developing holes. What is also not considered is what the leak cost his/her facility. Here are a few things to consider when trying to figure out what a stop in production actually cost you. First, ask yourself have I had to stop running due to filter failure? Next, how long did it take to find the leak, install a replacement, and clean the tube sheet? Most importantly, how much does 4-8 hours of added production hours and down time cost your facility? Let’s assume it cost $500/hour to run your plant. Let’s also say your facility has a great maintenance team that located a hole and got you back to production in two hours. Total cost $1,000. That is only after one filter bag failure! It is not uncommon to experience a few bag failures in a season. All of a sudden that $6,000 of savings, by washing your filters, is now down to $5,000.

One last thing to point out. One of the most obvious signs of weakening media is filters returned with repaired holes. A proper working filter will never have patch work done.

2. Cleaning damages media pores

One of two phenomenon’s happen when filters are washed over and over again. One outcome is the filter media will start to become very porous. This outcome is preferred by facilities because they will simply see great air flow in the baghouse. The delta pressure will be right where it needs to be. However, what is really going on behind the scenes is costing your plant money.

After a filter has been washed it can cause the pores to open up letting the dirty air just pass right through the media back out into the environment. The dust also makes its way back into your plant. A facility with filters like this will always be struggling with dust all around the plant. This accumulation of dust can be dangerous. In fact, overtime the accumulations of dust can lead to explosions. Not to mention the increased labor cost to keep the facility clean. The other side is your baghouse is no longer doing what it was intended to do, remove as much dust as possible. Open media allows dust laden air to exit the stack. This dust can cause nascence complaints by neighbors, or more seriously cause emissions violations. Depending on the size of your company, violation time, action taken can result in a fine ranging from $1,000 well up to $25,000 per day!

The next outcome of washing and drying filters is completely opposite of what was just discussed. What happens is the media becomes denser and denser after each clean. Whereas washing can cause the pores to open up, it can also compress the media together. The media starts to compact causing restricted air passages. A huller will receive his filters from the cleaner looking clean and dust free to only plug up quickly. Studies have shown that dense media has less movement than new media. This is a problem because during the day your filters are getting hit with a pulse of air to clean off excess dust. Movement of the media during a pulse is essential in the cleaning process. Eventually the media becomes too stiff and when hit with a pulse of air, it will not clean properly. In fact, many hullers report having to often stop production during the day, and turn on the offline cleaning cycle just to get the filters to breathe again. It is not uncommon for facilities to have to offline clean 20 min a day. While that may not sound like much consider this. Let’s use the typical work schedule where a facility runs 5 days a week for a 4 month production run. If they are forced to stop production for 20 min to offline clean, the hulling plant would be adding an additional 23 hours to the season to make up for the down time. That is almost an extra 3 days of running your plant to finish hulling all the product. If you are one of the plants having to stop production to clean off the filters, what does it cost you to add 3 extra days to production? If we keep to the $500/hour it cost to run your plant, you are looking at $12,000 in extra cost! That $6,000 of intended savings by washing your filters is now actually costing your plant $6,000! We are not done yet.

3. Cleaning will cause the finish of the media to be washed off

Polyester felts have a finish on the surface of the media. The top layer of a media is finished as “singed” or “glazed”. The media is placed on a hot roller that melts any small protruding fibers. It results in a surface that is smooth. This smooth surface helps dust fall off the media and prevents the filters from plugging up. What we see on filters that have been cleaned to much is, a complete removal of this finished layer (see below). The filters now have an extremely fibrous top layer. This is a problem when you think about incoming stick/branches/shell laden air, which is naturally fibrous entering into the baghouse at high speeds. It creates a phenomenon where the product get woven into the filter media. No cleaning system will be able to remove it at this point. Product will just build up on the filter as the season goes on. The result? A gradual reduction in air flow.