Quality filter bags are essential components in various industrial applications, playing a crucial role in ensuring environmental compliance and operational efficiency. Standard Filter, a leading name in the industry, excels in producing these vital components. This article takes you behind the scenes to uncover the meticulous process that goes into the manufacturing of quality filter bags at Standard Filter.

- The Foundation of Quality Filter Bags

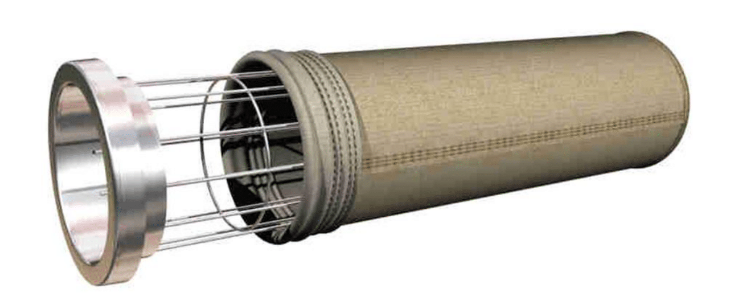

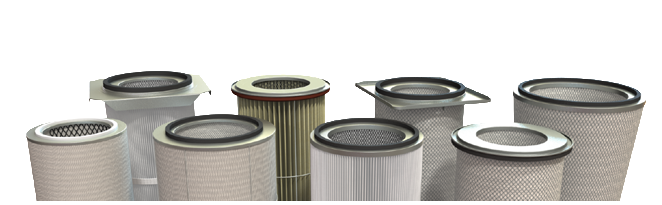

The journey of a quality filter bag begins with the selection of the right materials. Standard Filter prides itself on using only the highest-grade fabrics and materials and changes to withstand diverse industrial environments. These materials are chosen for their durability, efficiency, and compatibility with different industrial processes. Whether it’s polyester felt, polypropylene, or specialized high-temperature materials, each fabric is selected to provide optimal performance in specific applications.

- Design and Customization:

Each industry has unique requirements, and Standard Filter understands this well. The design process of their filter bags involves a thorough understanding of the specific needs of each industry they serve. This could range from high-temperature tolerance in metal processing facilities to chemical resistance in pharmaceutical manufacturing. The customization aspect is where Standard Filter’s expertise shines, as they tailor each product to meet the exact requirements of their clients, ensuring maximum efficiency and longevity.

- Advanced Production Techniques at Standard Filter:

At Standard Filter, the creation of filter bags is elevated by advanced production techniques. Leveraging the latest in manufacturing technology, the company ensures unmatched precision in every aspect of its filter bags. From the meticulous cutting of materials to the careful stitching and sealing, every step is optimized for accuracy and consistency. This automation not only streamlines the production process but also guarantees that each filter bag adheres to the company’s rigorous quality standards. Such commitment to employing advanced production methods underscores Standard Filter’s dedication to both innovation and quality in its products.

- Quality Assurance and Testing:

No product leaves the Standard Filter facility without undergoing rigorous quality assurance and testing. This phase is crucial in maintaining the high standards for which Standard Filter is known. The filter bags are tested for various performance parameters, including durability, filtration efficiency, and resistance to wear and tear. These tests ensure that every filter bag can withstand the harsh conditions it will face in industrial settings.

- Packaging and Distribution:

Once manufactured and tested, the filter bags are carefully packaged for distribution. The packaging process is designed to protect the bags from damage during transit, ensuring they arrive at their destination in perfect condition. Standard Filter has a global distribution network, enabling them to supply their high-quality filter bags to a wide range of industries around the world.

- Continuous Improvement and Innovation:

The manufacturing process at Standard Filter is not static; it is a hub of continuous improvement and innovation. The company invests in research and development to refine its manufacturing techniques and explore new materials and technologies. This forward-thinking approach allows Standard Filter to stay ahead of industry trends and meet the evolving needs of their clients.

Conclusion:

The manufacturing process of quality filter bags at Standard Filter is a blend of precision, innovation, and a deep understanding of industrial needs. This process is crucial to the production of filter bags that not only meet but exceed industry standards. Standard Filter’s unwavering commitment to quality and continuous improvement places them at the forefront of the filtration industry.